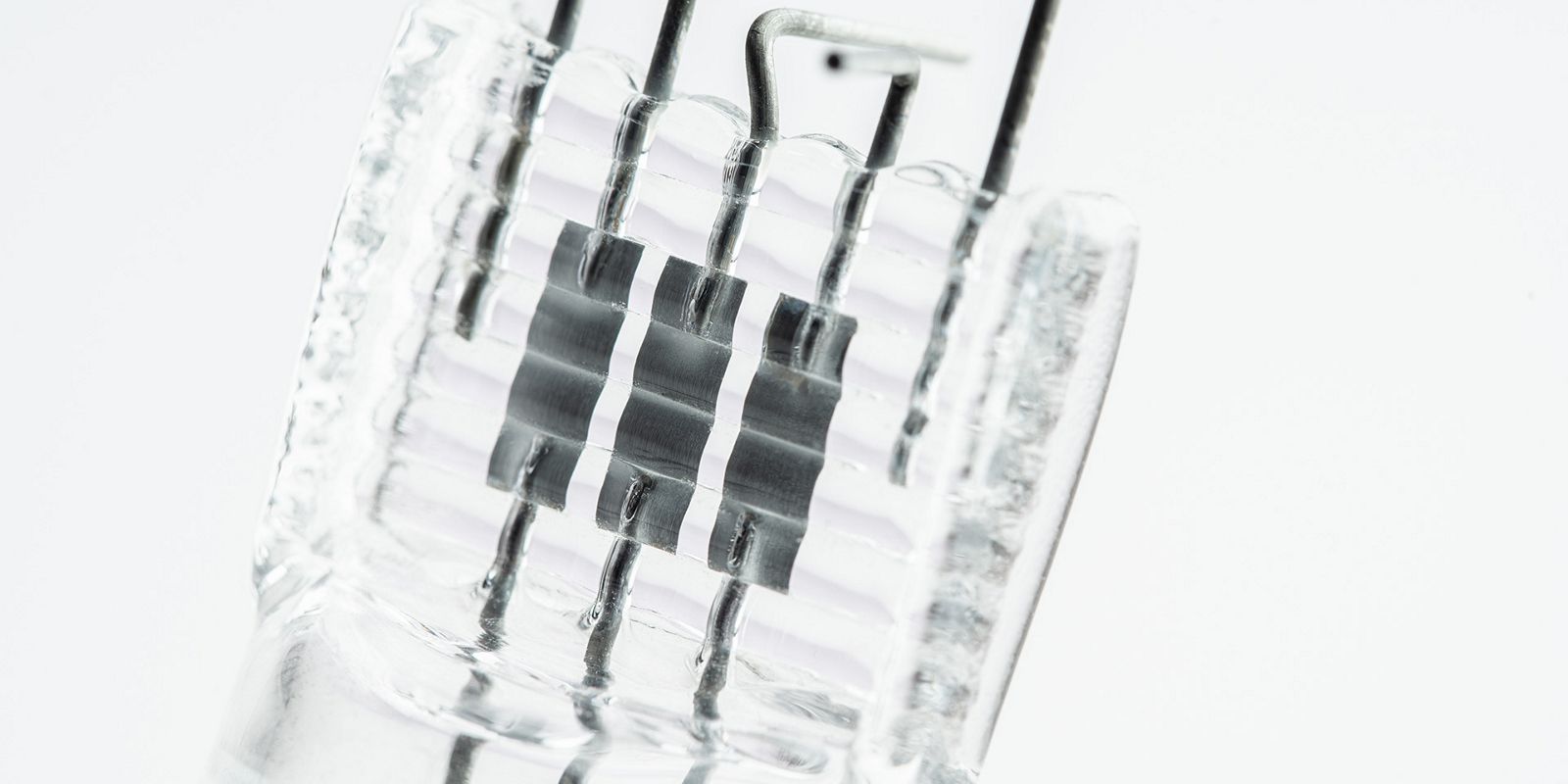

Why do molybdenum-yttrium oxide (MY) and quartz glass adhere so well?

During etching, the dopants in the MY are released at the material surface. As soon as the molten glass comes into contact with the metal

surface, the Y2O3 dopants and the quartz glass (SiO2) form a chemical bond that increases the adherence between the ribbon and the glass. We reduce the risk of leakages due to the low stress between the glass and the metal.