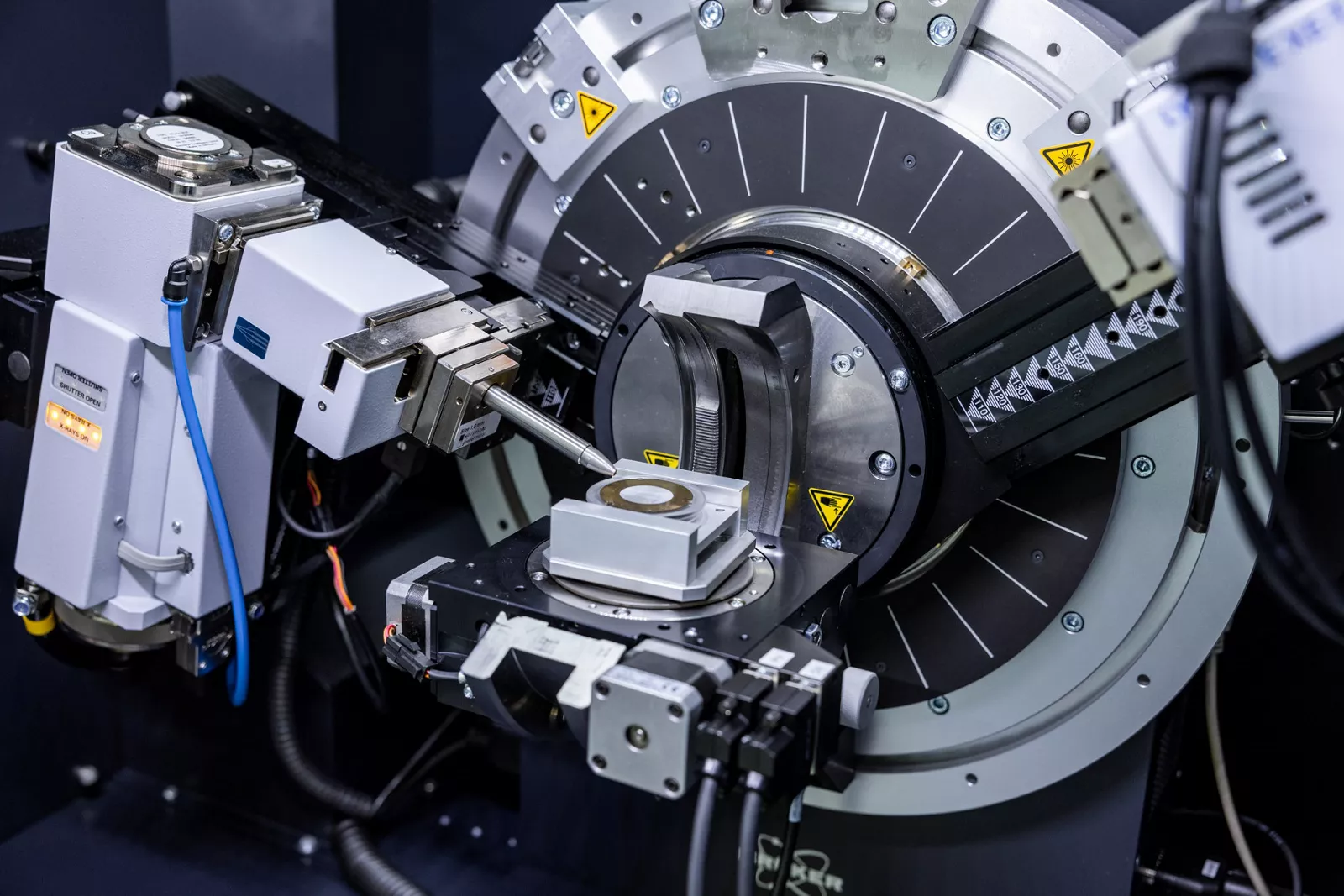

Accredited since 1997

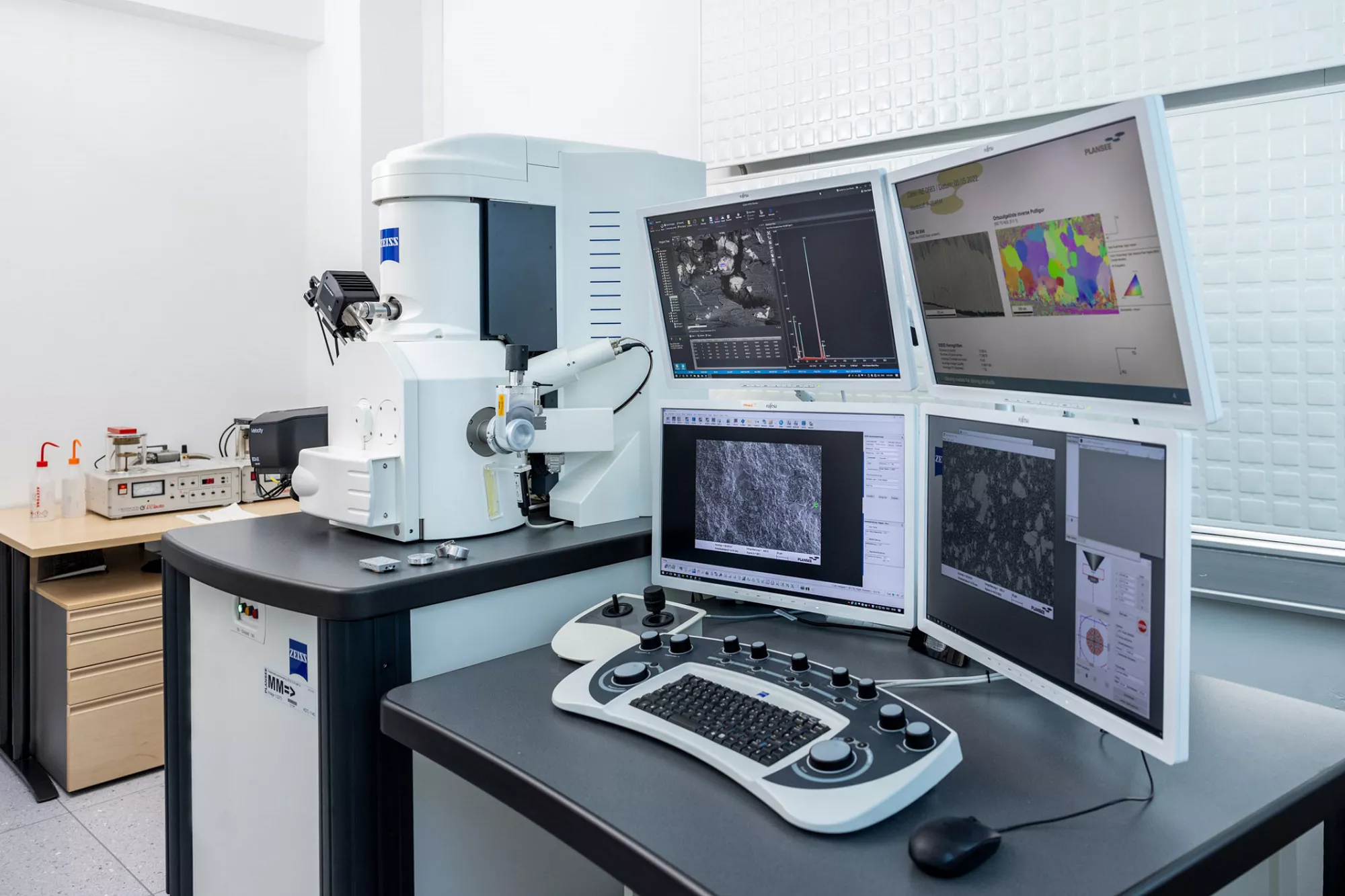

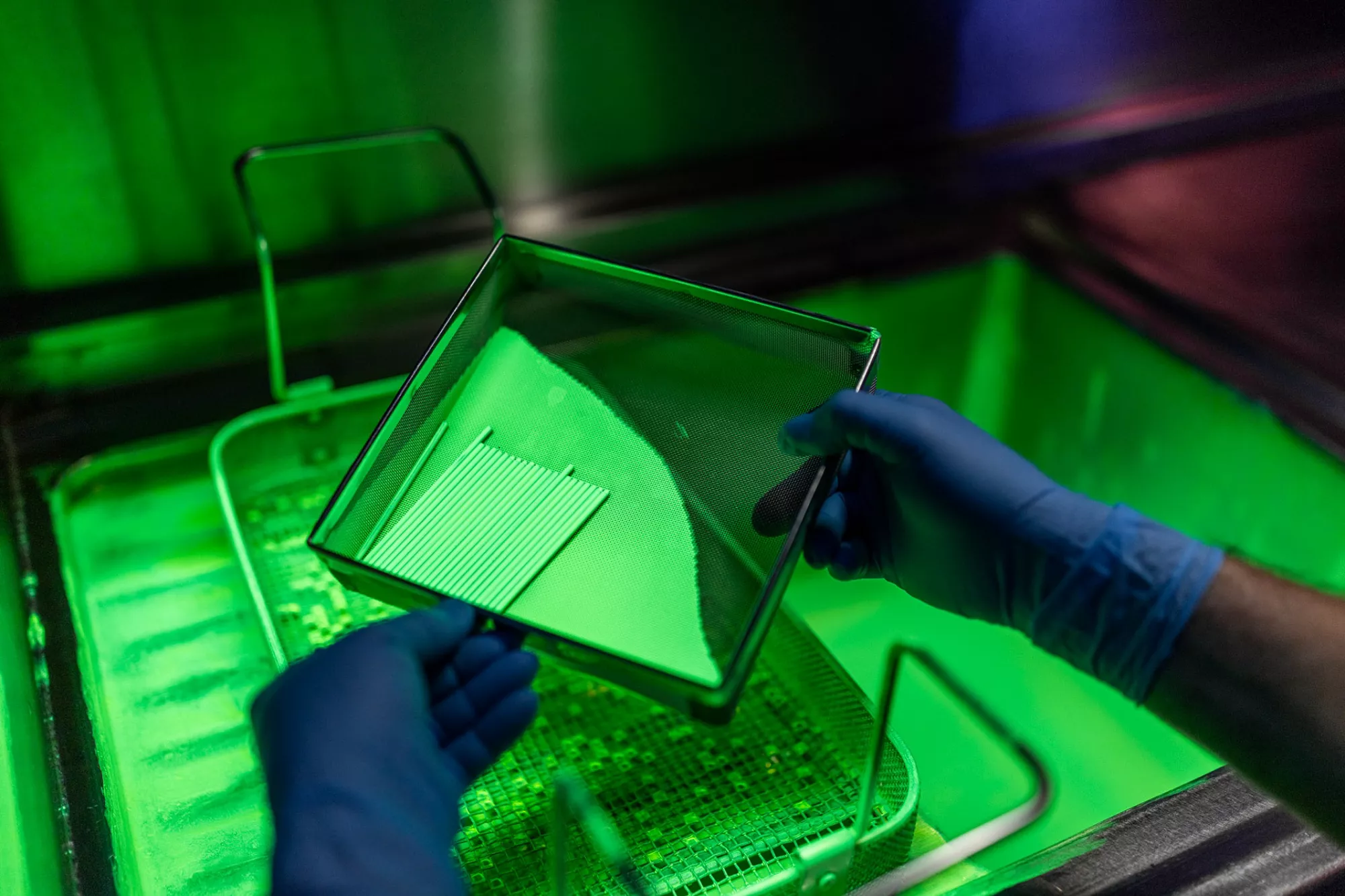

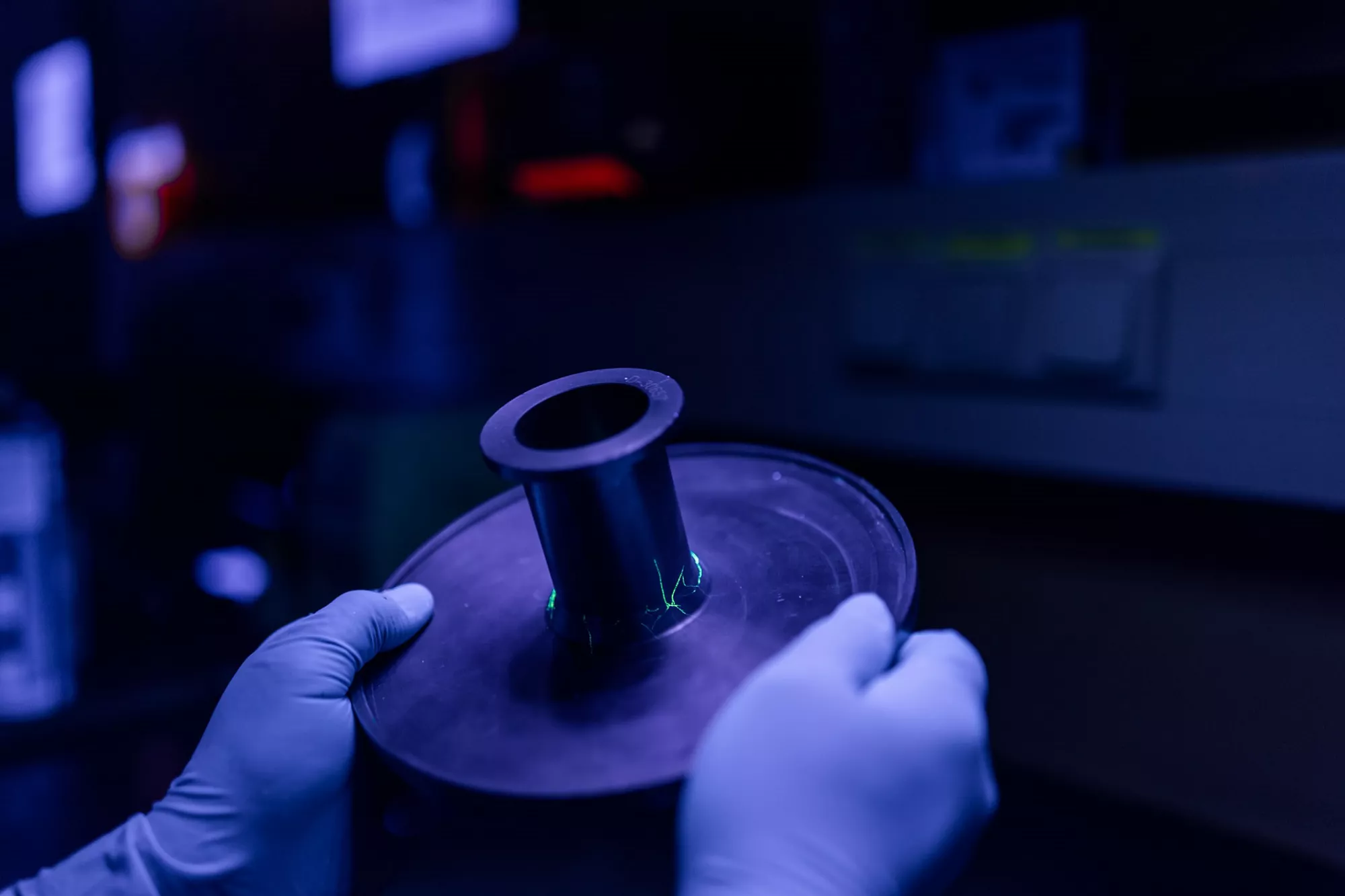

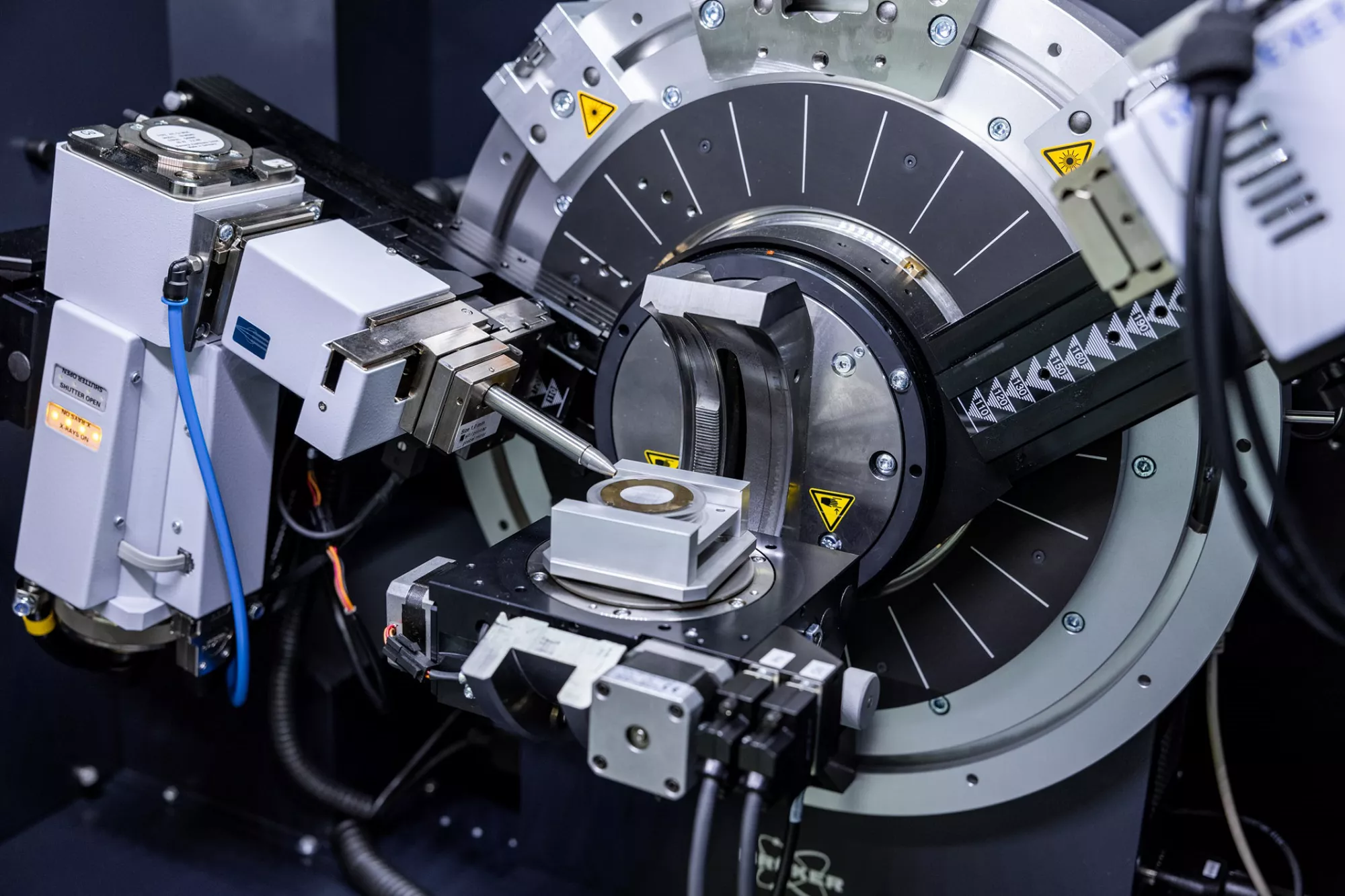

When you select a laboratory for your testing, calibration and measurement needs, you must be sure that this laboratory can offer you precise and reliable results. Our testing laboratories have therefore been accredited by the responsible Ministry according to ISO 17025:2017. We do this so we can confirm that we are meeting current requirements related to quality, competence, and equipment.