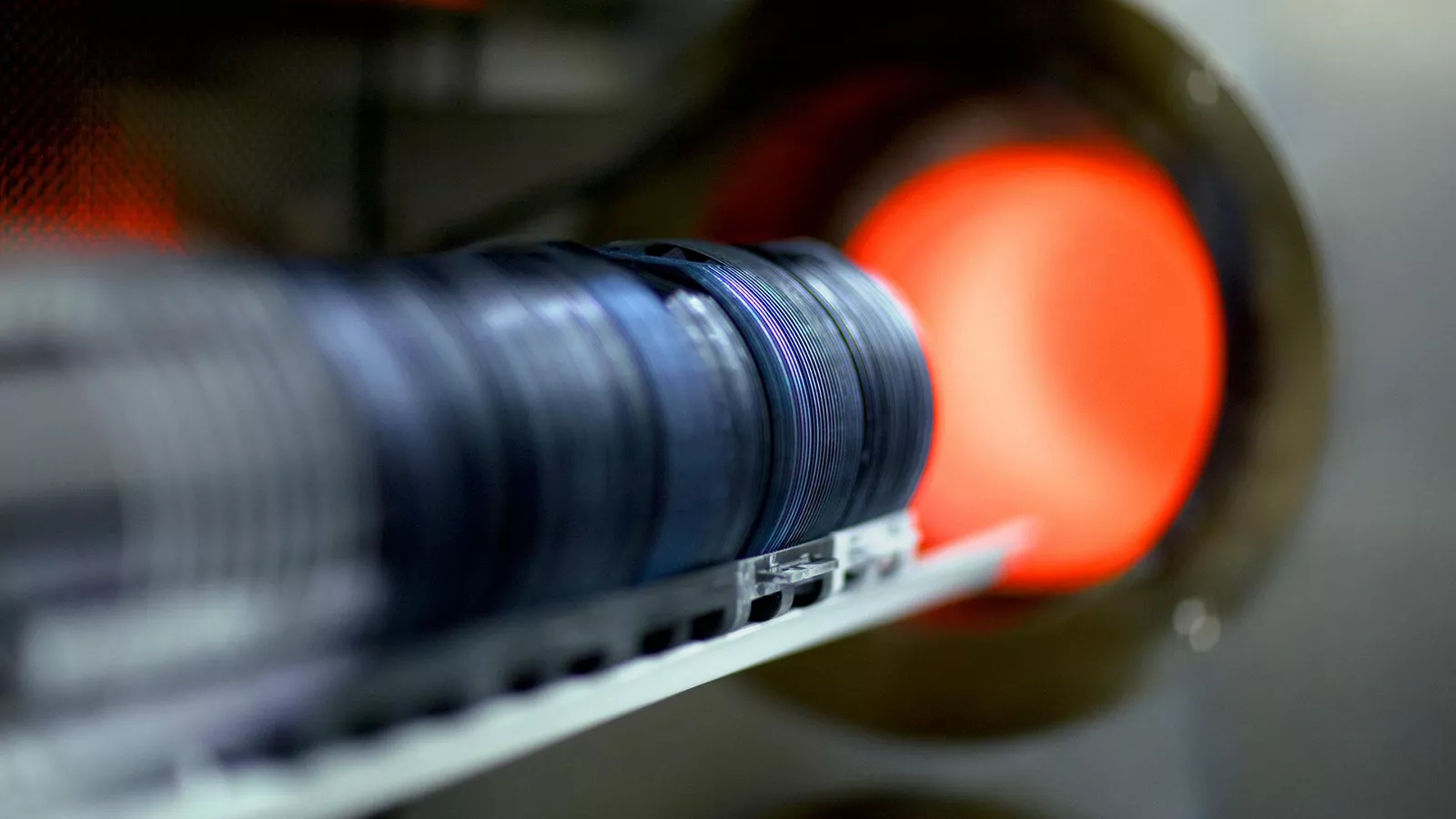

To achieve their maximum performance, many products must undergo lengthy and energy-intensive heat treatment such as an annealing process. One of the ways of annealing these items is to use electrically-heated high-temperature furnaces with zone temperature regulation, in which the products are arranged in layers. The temperature that must be achieved is preset for each heating zone. "As the annealing process requires relatively high energy use, this process needs to be optimized with respect to both conserving resources and saving on expensive energy costs," explains Gerfried Weiss, head of production at Plansee. To this end, a research project has been launched together with the AIT Austrian Institute of Technology.

09/12/2022

High energy savings through optimization of processes

The minimum annealing time must be adhered to

During an annealing process, the inside of the furnace heats up until the specified zone temperature is reached. This temperature is then maintained for a certain length of time to guarantee that the products are heated to the specified temperature and are annealed for a minimum annealing time at this temperature. The products are then cooled down again.

In practice, precise adherence to this minimum annealing time is important, as the temperature progression in the products is heavily dependent on the load of the furnace and the temperature progression does not follow the zone temperature exactly due to thermal inertia of the materials. Furthermore, it is extremely difficult to measure the temperature (up to 1800 degrees Celsius) of the heat-treated objects directly: suitable load thermocouples are expensive, delicate, and difficult to install, while the software models for temperature estimation are very complex. For this reason, in practice there is a tendency to play it safe and choose a longer duration for the annealing process. If this is too short, the annealing material is not annealed homogenously for long enough, which has a negative effect on the material properties. If it is too long, time and energy are wasted.

To optimize the annealing process, Plansee has launched the ThermoTec project together with the AIT Austrian Institute of Technology. "In this project we have combined Plansee's expertise in materials and processes with our knowledge of regulating difficult and complex processes," explains AIT project manager Martin Niederer. An algorithm has now been developed through complex measurements, analyses, and modeling, which can be used to reliably set the desired minimum annealing time for any load.

High energy and time savings with consistent quality

Experimental validation of the algorithm in more than 230 annealing operations on a furnace over the course of a year revealed that the holding time of the process could be reduced by 20 percent on average. The reduction in energy consumption and CO2 emissions is equivalent to that of 15 homes.

Accompanying material tests showed that the product quality remained unchanged at a high level. What's more, optimization reduced the total duration of the process by almost 12 percent, which enables better utilization of the furnace. "The process ensures precise adherence to the minimum annealing time, which results in energy savings and thus heating costs, as well as improved throughput with consistently high quality," says Tobias Glück, head of the Competence Unit Complex Dynamical Systems.

Use of the new process in practice

The process is now being used in production operations at Plansee and is contributing toward reducing the energy demands of the production department. "The new algorithm can be integrated into the existing furnace control and can therefore be transferred to other furnaces with ease. We will continue to roll this out over the coming months," reports Bernhard Mayr-Schmölzer, project manager at Plansee.

About the AIT

The AIT Austrian Institute of Technology is Austria's largest research and technology organization (RTO). With its seven centers, the AIT examines the central infrastructure issues of the future and sees itself as a highly specialized research and development partner for industry. The Center for Vision, Automation & Control (VAC) at the AIT Austrian Institute of Technology is a research unit that makes use of the opportunities afforded by automation and digitalization to initiate and drive forward innovations for industry.