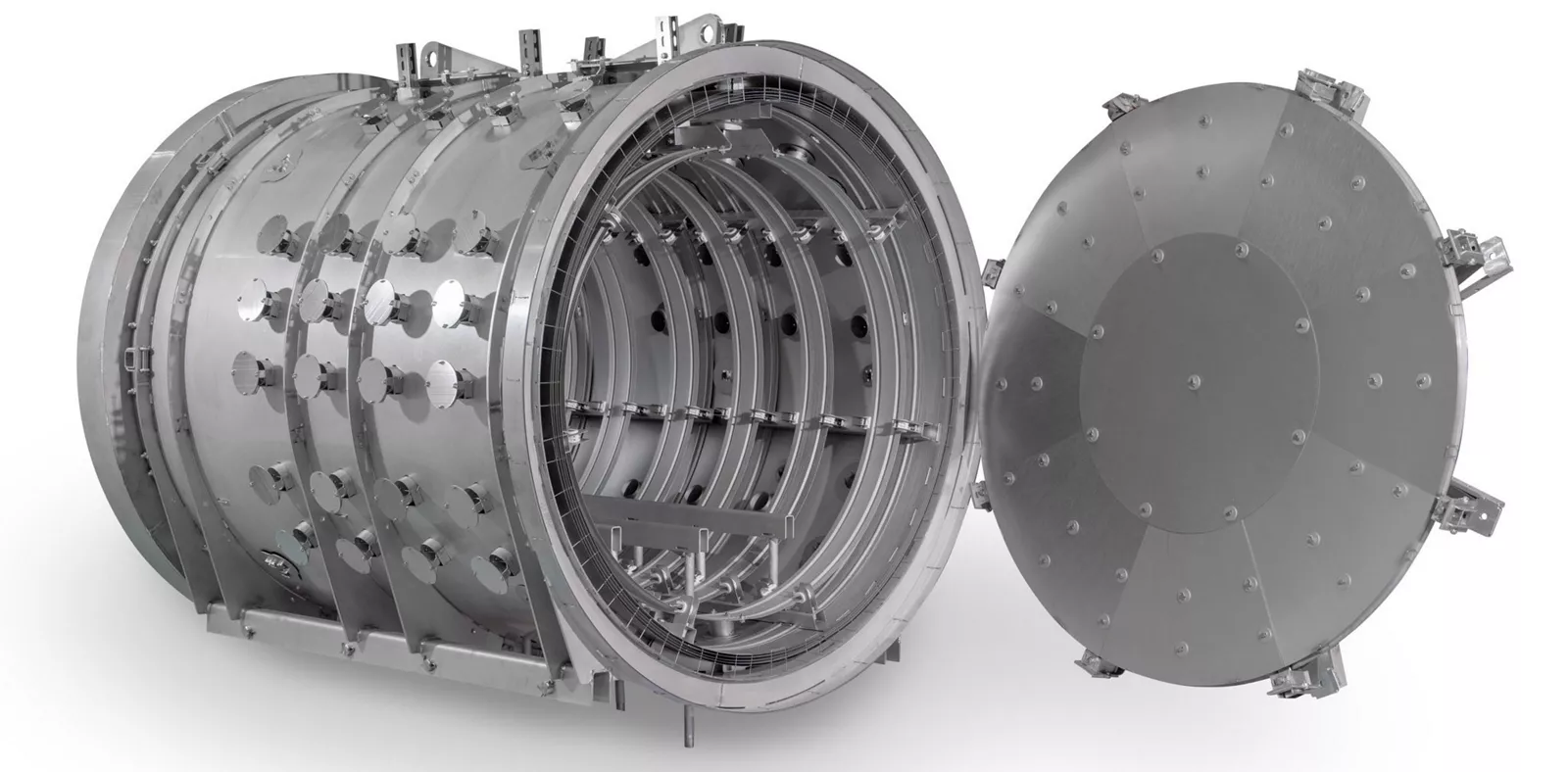

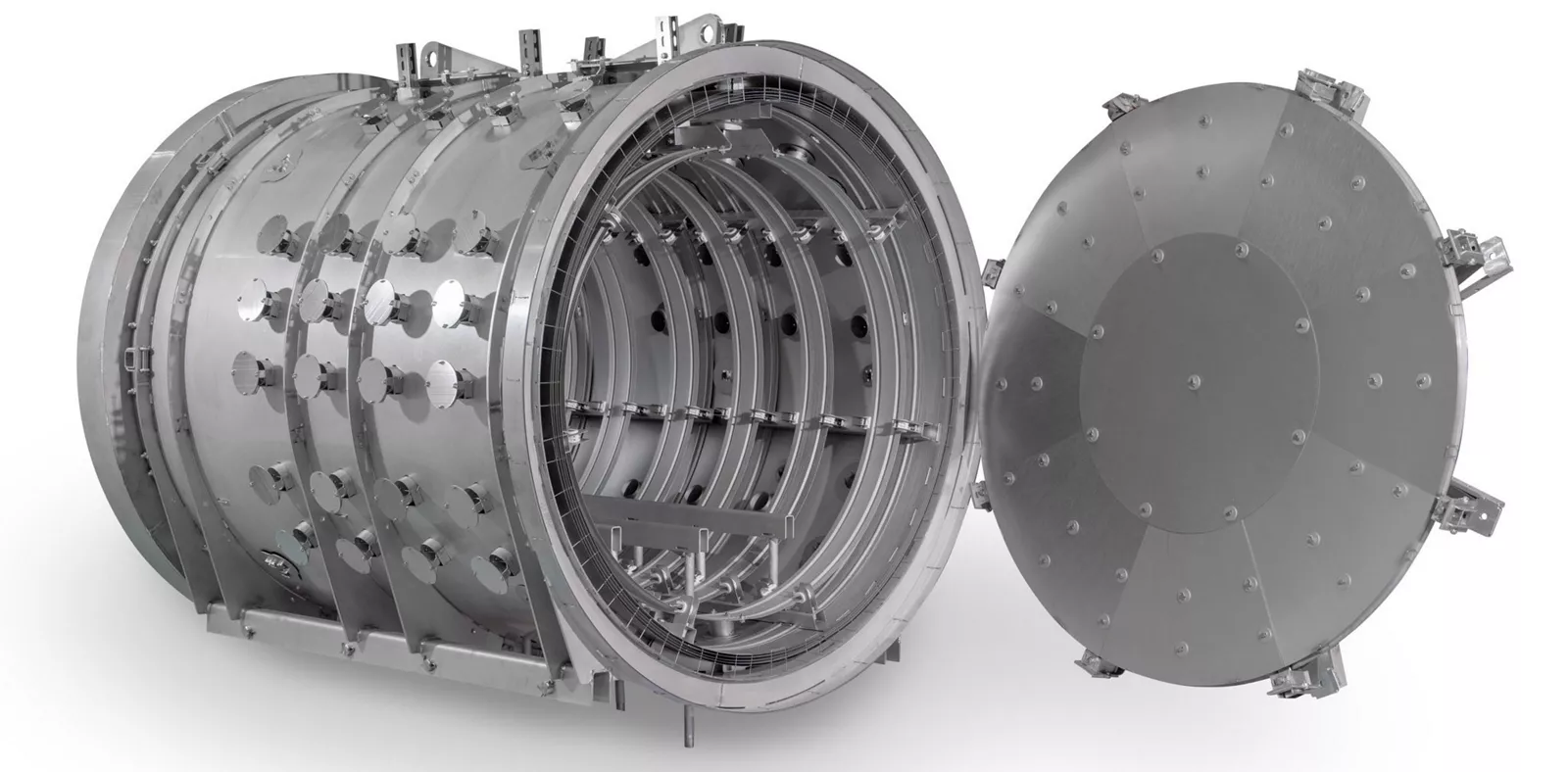

In February 2024, two "New Generation Premium Plus Hot Zones" with a usable area of 600 x 600 x 900 mm were delivered to a European customer. The hot zones are used for the annealing of aviation components in the aerospace industry.

17/04/2024

Right before the start of Thermprocess trade show in Düsseldorf in June 2023, Plansee presented the new generation of hot zones for high-temperature processes. These are characterized by maximum energy efficiency. The response from customers was positive right from the start and the first orders were received shortly after the trade fair.

In February 2024, two "New Generation Premium Plus Hot Zones" with a usable area of 600 x 600 x 900 mm were delivered to a European customer. The hot zones are used for the annealing of aviation components in the aerospace industry.

"We have been working with this renowned customer for around 10 years. They rely on our comprehensive expertise and value the technical advice provided by our engineers," says Peter Mallaun, Application Manager in the Business Segment Engineering.

Production is carried out using standard components such as gas nozzles, power connections and new heater suspension.

Our customers can configure their hot zone individually themselves. Calculations in the background lead to numerous variants, from which the engineers select the one that is technically the most advantageous and the most cost-effective to manufacture. Suitable variants can then be selected and transferred to an automated, parametric CAD model.

The new generation of hot zones is designed for maximum energy efficiency. Thanks to numerous technological optimizations, Plansee has succeeded in reducing the energy consumption of the high-temperature process by up to 27% on average compared to the industry standard.

Would you like to find out more about the technical features and innovations of Plansee hot zones?