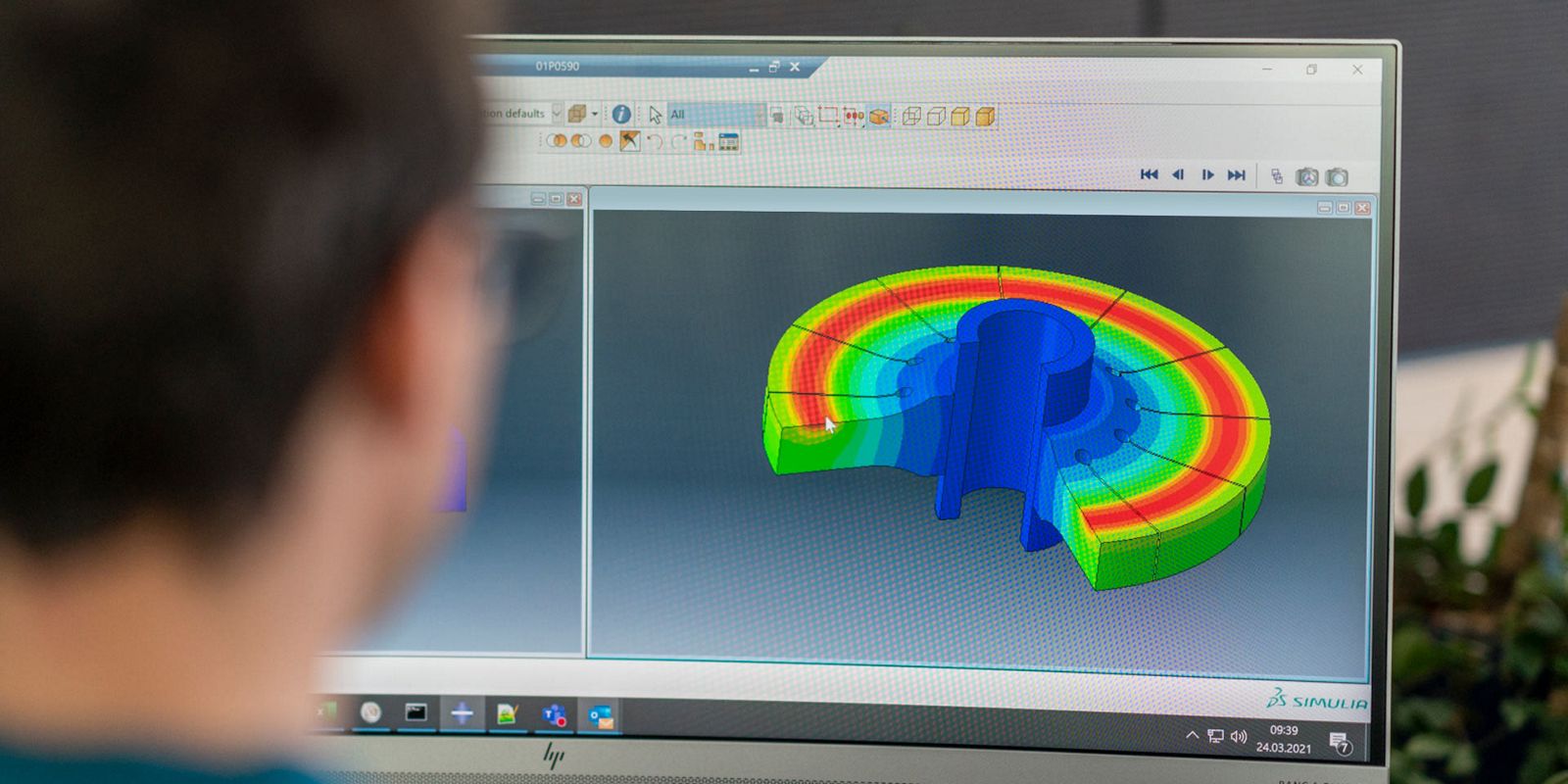

Simulations

We carry out simulations using the Finite Element Method (FEM), Computational Fluid Dynamics (CFD), and Molecular Dynamics (MD) on the basis of our comprehensive material database.

Maximum quality, precision, and reliability are essential in the field of X-ray technology. We are able to guarantee all of these things thanks to decades of experience. We also strive to further increase the performance of components in collaboration with our customers and develop new designs according to customer requirements. Our experienced expert team of researchers and developers therefore works continuously on optimizing our materials and production processes.

First-class database for materials

FEM, CFD, and MD simulations

Customer-specific designs

Support for risk- and error analysis

Support for root cause analysis and optimization

We carry out simulations using the Finite Element Method (FEM), Computational Fluid Dynamics (CFD), and Molecular Dynamics (MD) on the basis of our comprehensive material database.

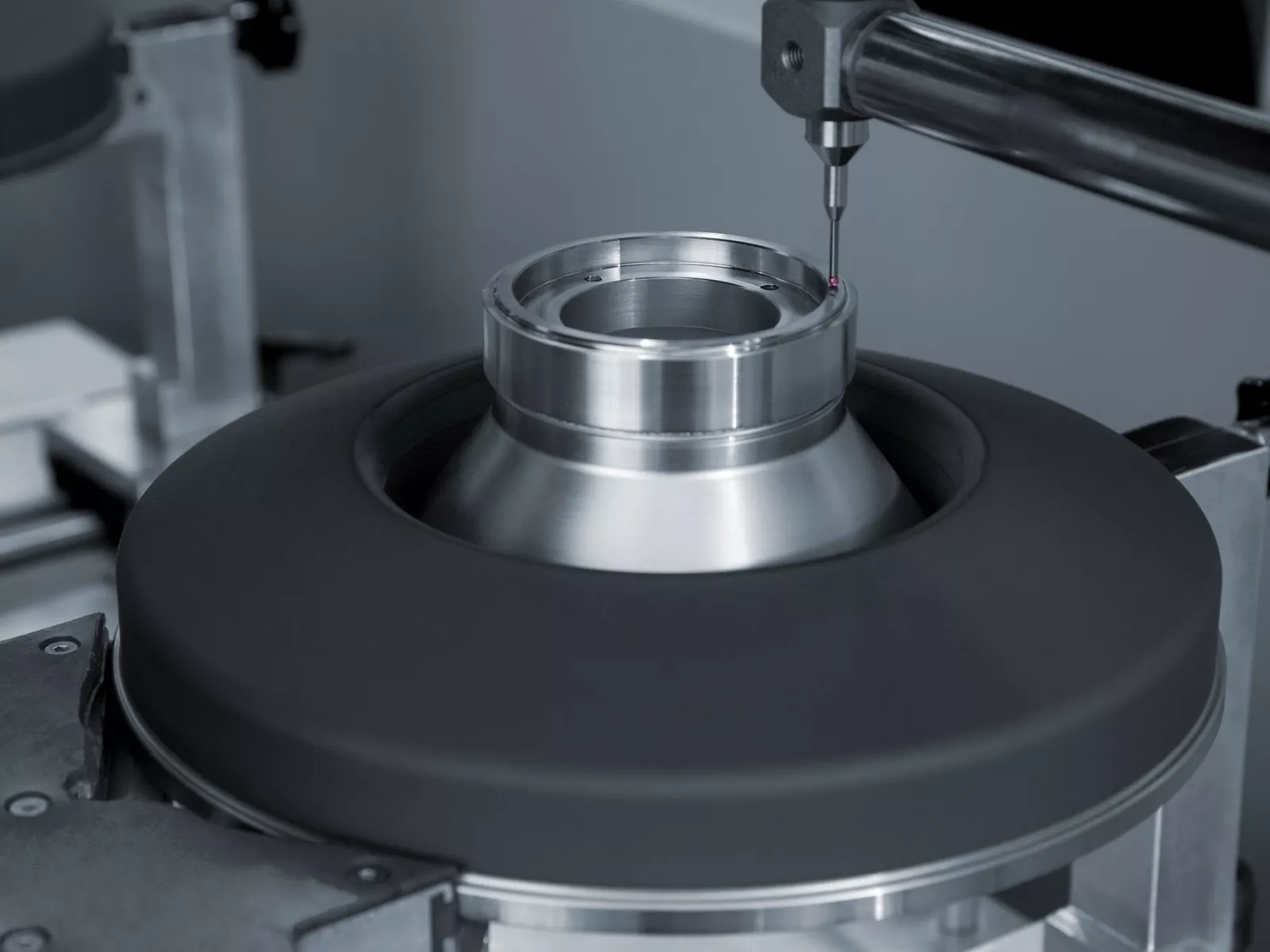

We carry out mechanical tests as well as chemical and metallurgical analyses in our accredited testing laboratory. We have expertise in numerous non-destructive test procedures such as ultrasonic testing, eddy current testing, and thermographic investigations.

Whether it's material testing and analysis or the development of tailor-made solutions, contact us to find out more about what we can do. We'll be happy to support you with our experience, expertise, and technologies.