Low corrosion ensures a long service life for the electrodes

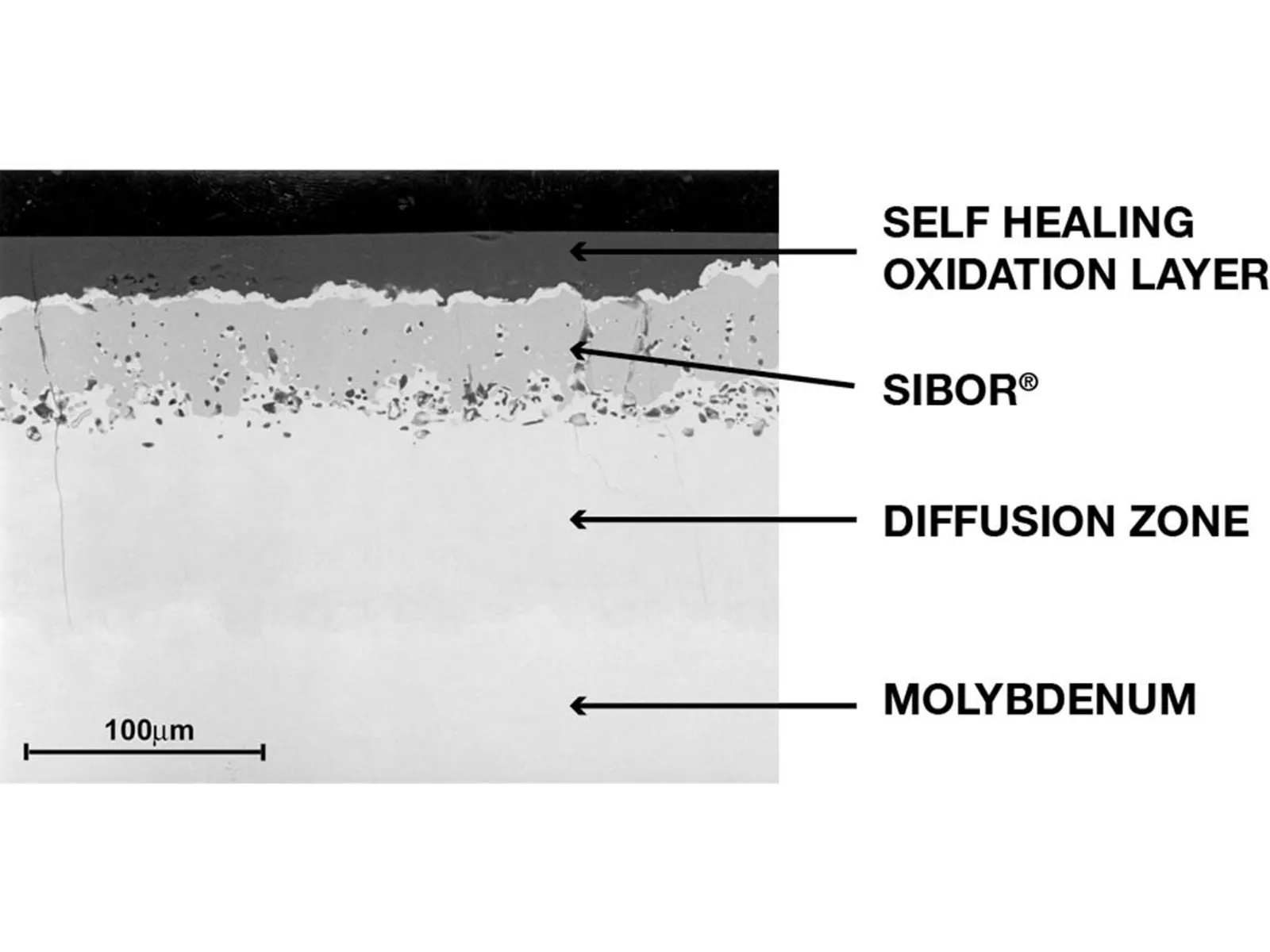

Molybdenum exhibits excellent corrosion resistance with regards to most glass melts. Low material removal rates are the deciding factor for a long service life of the glass melting electrode and also have a major influence on the final quality of the glass.