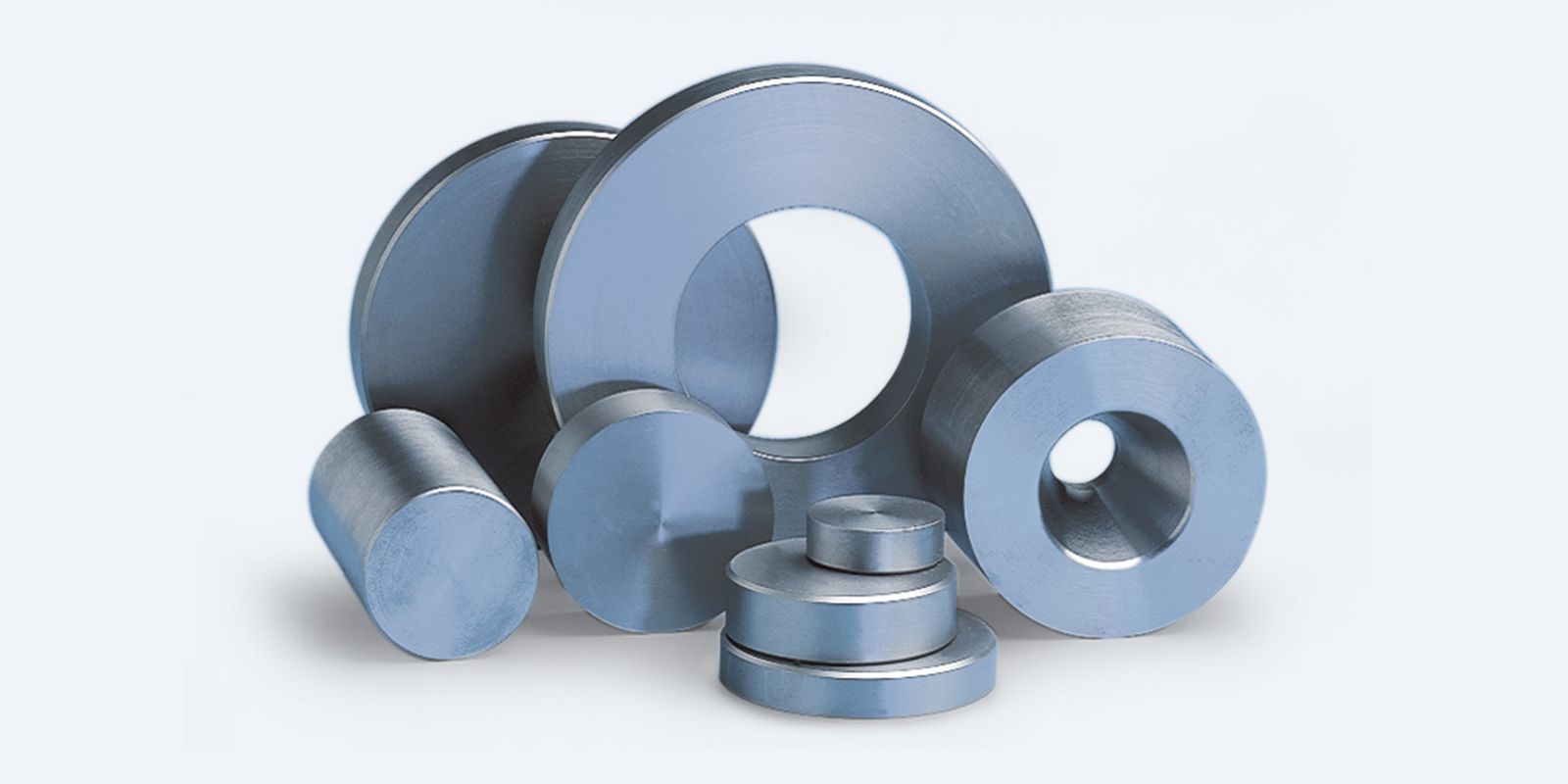

Inserts made of molybdenum-hafnium carbide for extrusion dies

Extrusion presses are used to form non-ferrous metals such as brass, copper-nickel, and aluminum-bronze, as well as stainless steel, into rods, wires, or tubes. The metal blank is first heated to its forming temperature and then is pressed through the die using a ram. This gives the metal its external shape.

Extrusion dies are exposed to high mechanical pressures. A very high level of frictional heat is also generated between the die and the workpiece during processing. By adding small quantities of hafnium carbide, we get our molybdenum ready for a long service life in your extrusion press.

Your advantages at a glance:

Optimum dimensional stability

Low tendency of crack formation for edged pressed profiles

High high-temperature stability

Good thermal hardness

Low thermal expansion

High thermal conductivity

Our product specification available for download:

Molybdenum-hafnium carbide (MHC) is particularly temperature-resistant, has a high thermal conductivity and a low coefficient of expansion. MHC retains its shape even at operating temperatures up to 1550°C. MHC is suitable for use in die inserts for temperatures up to 800°C. At higher temperatures, we recommend using MHC for full dies.

We supply our MHC dies in disc form with or without a drilled starter hole.

The best way to machine MHC

Drilling:

- Carbide ISO HW-K15

- Point angle: 120 degrees

- Clearance angle: 10 degrees

- Cutting speed: 80 m/min (with cutting emulsion)

- Feed: 0.01 – 0.05 mm

Turning:

- Carbide ISO HW-K15

- Rake angle: 25 degrees

- Clearance angle: 7 degrees

- Cutting speed: 100 – 150 m/min (with cutting emulsion)

- Feed: 0.05 - 0.20 mm

- Cutting depth: up to 3 mm

Grinding:

- Silicon carbide grinding wheel

- Speed: 28 m/s

Spark erosion:

- WCu electrodes

- Wire eroding possible

If you have any questions regarding machining our materials, we would be happy to help.

Tips on using your new die:

- Temperature

Before the first extrusion operation, heat the die to at least 350°C. The temperature of the die should not fall below 250°C during the intervals between press operations. After use, cool the die to ambient temperature and please note that MHC dies must not be cooled with water.

- Shrinkage of die inserts

Despite the low coefficient of thermal expansion, the shrinkage of MHC inserts is very manageable at 5.6 · 10-6 m/m · K. The application of caulking at various points prevents the insert from being pulled out of its holder. During the first extrusion operation, the die may retract by 0.1 to 0.15 mm in the area of the sliding surface which imparts the shape to the workpiece. This effect disappears again after the appropriate correction has been made during subsequent pressing processes. After correction, the die remains non-deformable and dimensionally stable.

- Hairline cracks

Sometimes hairline cracks may occur at the inlet radii. This does not impair the functioning of the part. Only if the pressed material adheres to these hairline cracks would it be necessary to rework the die. We recommend manual polishing using a fine linen cloth and diamond paste for this purpose.