Please see the product specifications for details about our products:

Molybdenum glass tank reinforcements

In the glass melt tank, the refractory bricks are exposed unprotected to the aggressive glass melt. This results in corrosion, abrasion, and erosion, which significantly reduces the service life of the glass melt tank. In addition, this wear can also have a negative impact on the glass result as well as the glass quality.

Platinum and molybdenum are the only metals that are able to withstand the high temperatures and chemical corrosion caused by the glass melt. Platinum is very expensive, whereas molybdenum is the economical, high-performance alternative.

Your advantages at a glance:

Highest purity for bubble-free application (min.

99.97%)Excellent

corrosion resistanceHigh creep

resistanceOptimum protection against oxidation via a Sibor® coating

Customer-specific

solutionsIn-house construction and manufacturing

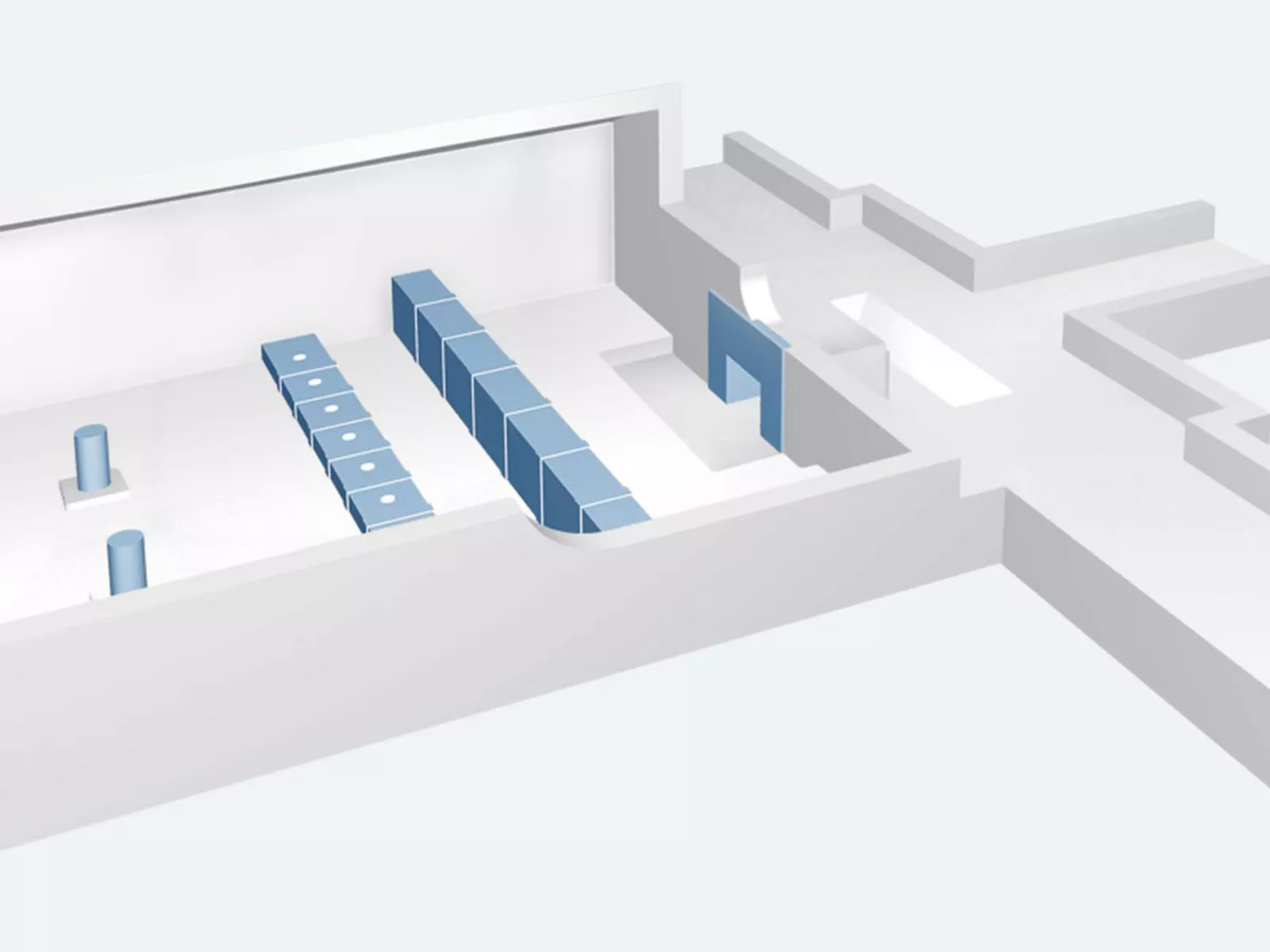

Schematic representation of Plansee tank reinforcement components in a glass melt tank

Molybdenum exhibits excellent corrosion resistance with regards to most glass melts. Low material removal rates are the deciding factor for a long service life of glass melt components and also have a major influence on the final quality of the glass.

- Corrosion in glass melt tanks: material comparison

Plansee |

Standard |

|

| Major and minor components |

Minimum content [%] |

ASTM B387 (361) |

| Mo | 99.97% a | Remainder |

| Impurities | Maximum values [µg/g] | Minimum values [µg/g] |

| Guaranteed | ||

| Al | 10 | - |

| Cr | 20 | - |

| Cu | 20 | - |

| Fe | 20 | 100 |

| K | 20 | - |

| Ni | 10 | 50 |

| Si | 20 | 100 |

| W | 300 | - |

| C | 30 | 100 |

| H | 10 | - |

| N | 10 | 20 |

| O | 40 | 70 |

| Cd | 5 | - |

| Hg | 1 | - |

| Pb | 5 | - |

a) Metallische Reinheit ohne W

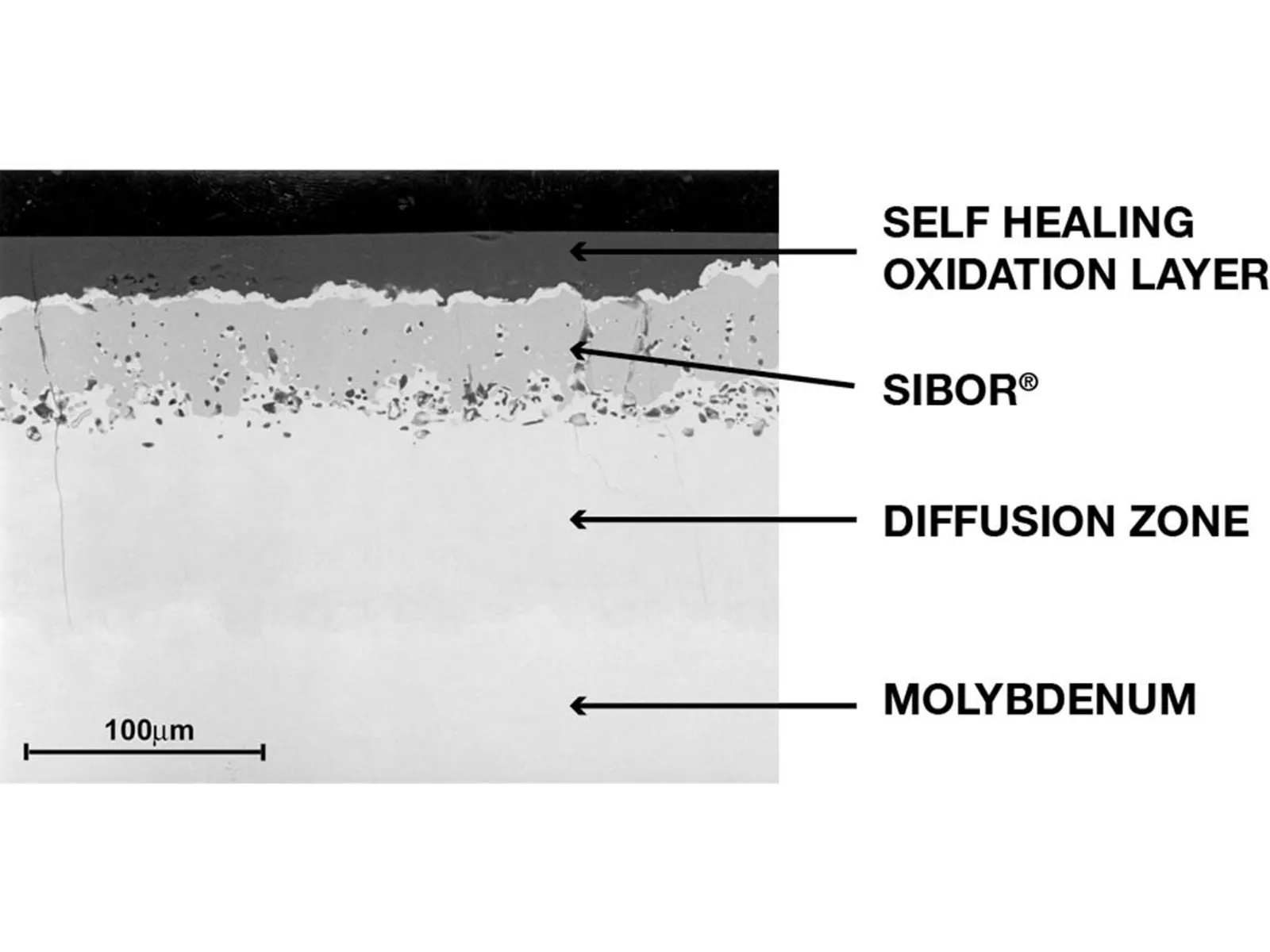

Sibor® – reliable protection against oxidation

Molybdenum begins to oxidize at over 400°C. We developed Sibor® – our oxidation protection for molybdenum – to protect tank reinforcement components from oxidation during the heating process. Sibor® protects molybdenum from oxidation up to 1700°C (3092°F). The very hard, dense coating creates a diffusion barrier along the base material and forms an SiO2 seal against the air. This protects the material against oxidation for up to 5000 h depending on the operating temperature.

Our know-how to protect your glass melt tank:

- Sibor®-coated molybdenum glass tank reinforcements for protecting the ceramic stones (throat, doghouse, crosswall, bubbler, etc.)

- Molybdenum profiles for enhancing the ceramic stones

- Sintered flow and outflow pipes

- Floor drains and gutters made of molybdenum

We can customize the design of our glass tank reinforcements to the individual requirements of your glass tank. We work with very strict tolerances so that everything will fit perfectly. You can rely on our experienced furnace designers.

Excellent quality from a single source

We produce all of our molybdenum tank reinforcement components in-house, from the raw material to the coated final product. We only use the purest molybdenum oxide as the source material. This is how we guarantee that our tank reinforcements will not have any impurities. Our molybdenum is guaranteed to be 99.97% pure.