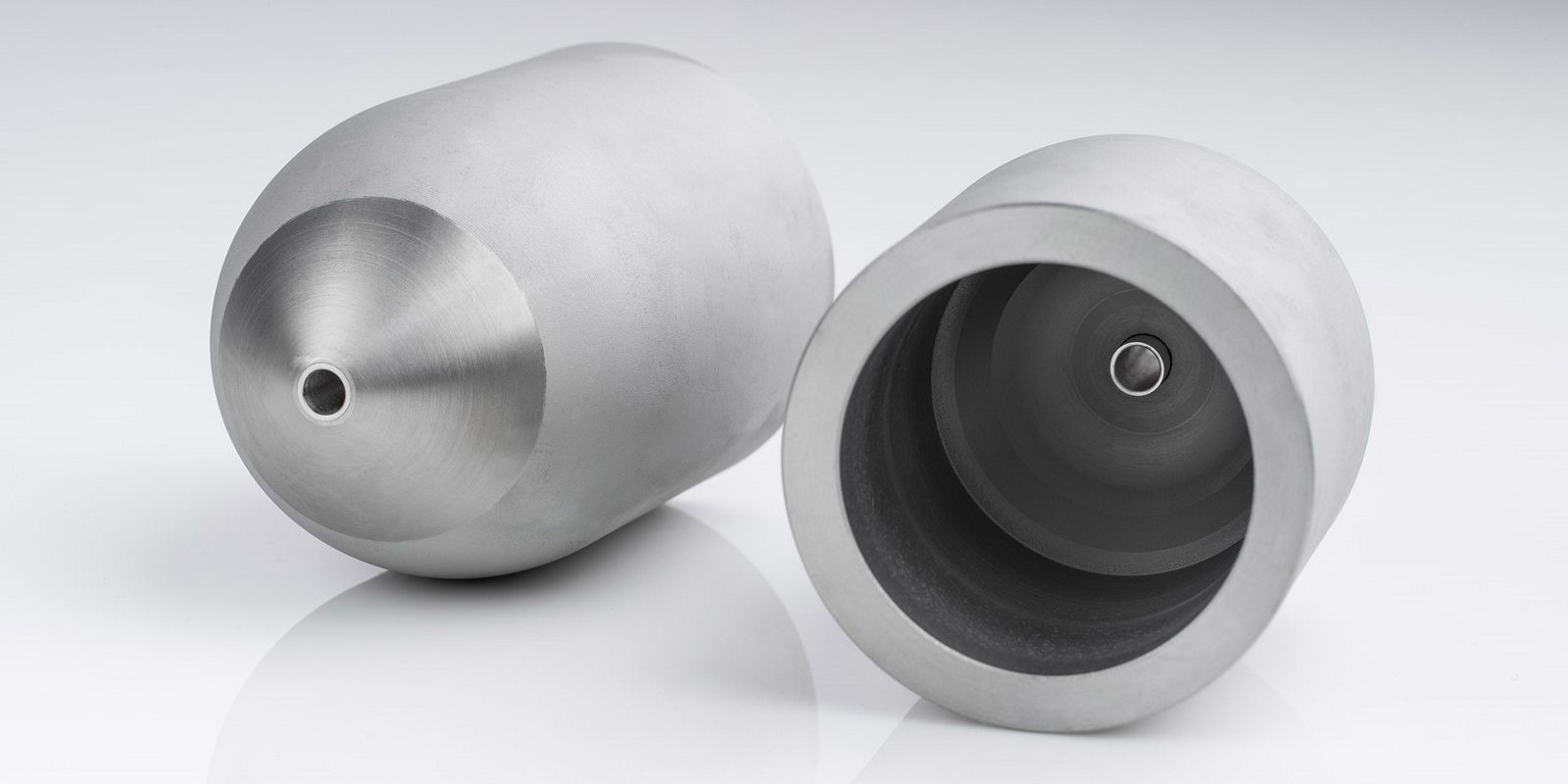

Quality through durability

A precisely dosed, centric melt spray is indispensable for the quality of the final product. We can ensure this with our high-temperature-resistant nozzles made of molybdenum and tungsten. With the addition of iridium- and rhenium inserts, they are especially durable as well as wear- and corrosion-resistant. We have also developed a special technique for joining the precious metal insert and the refractory metal nozzle, allowing the highest service lives to be achieved.