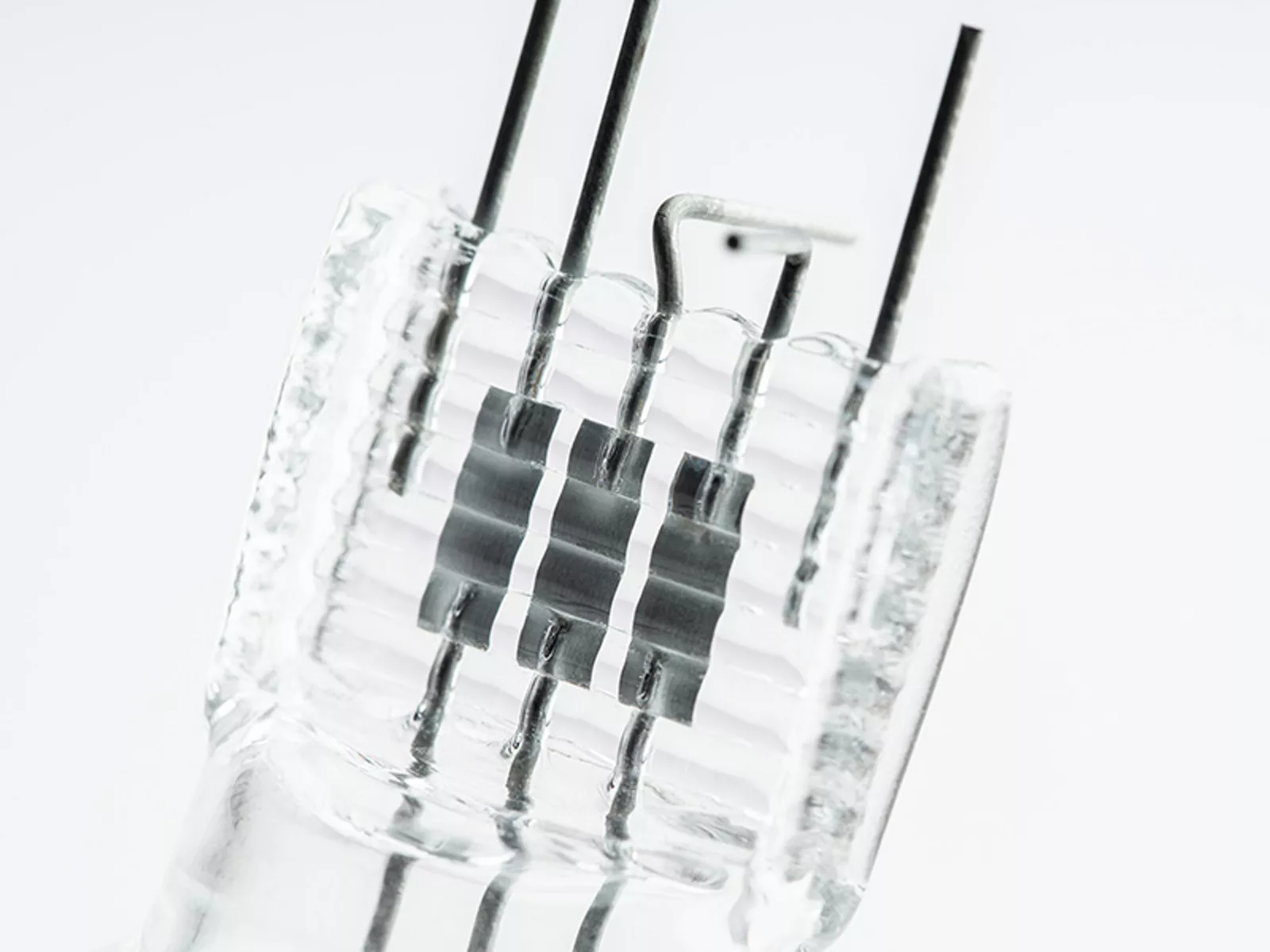

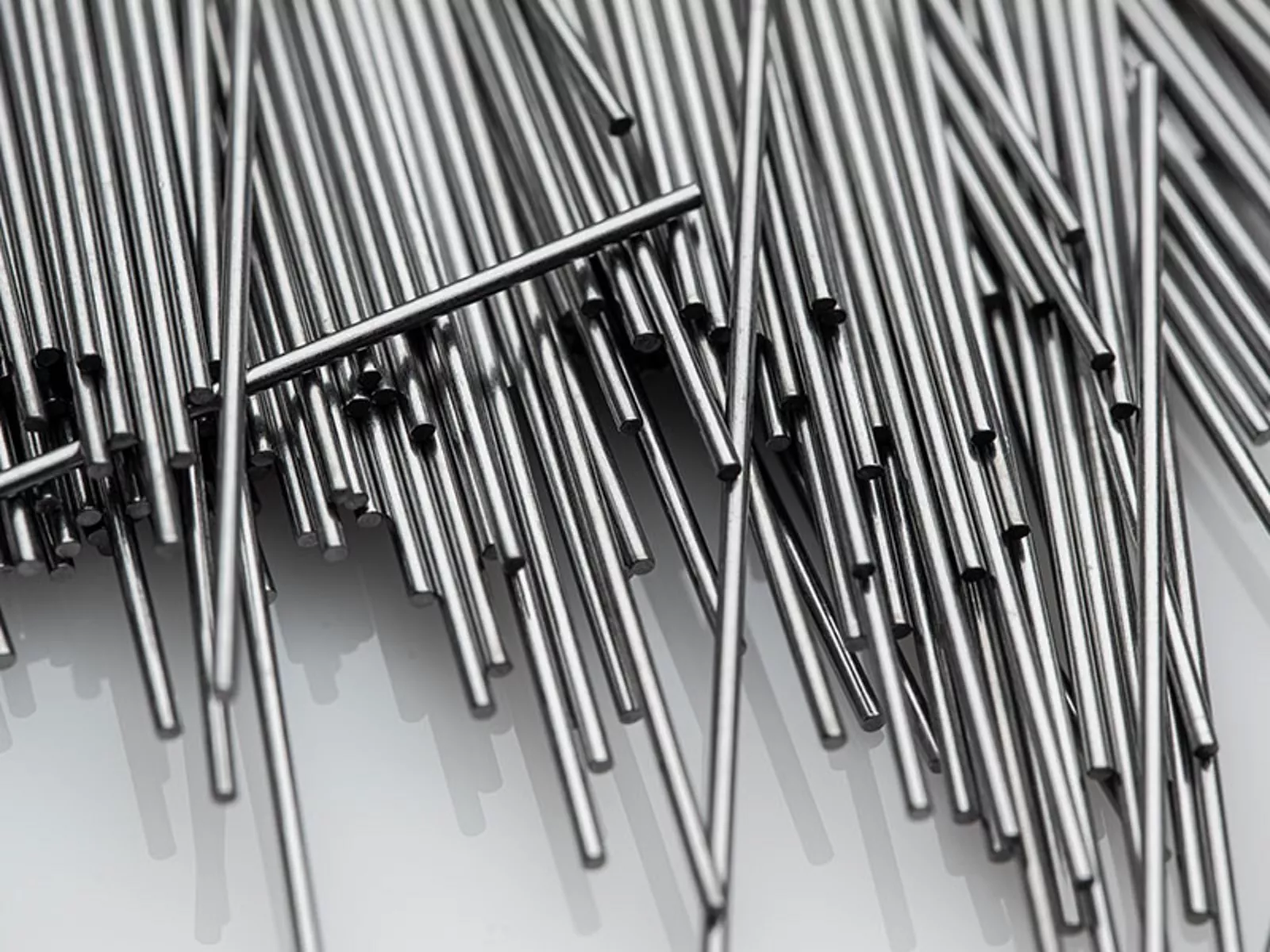

The stabilized microstructure and modified recrystallization behavior prevent the premature embrittlement and fracture of our material. A high level of resistance to oxidation is particularly important at operating temperatures of over 300°C: the oxidation rate of ML is considerably lower than that of pure molybdenum. ML has a particularly fine-grained fiber structure. After recrystallization, the material forms a stacked microstructure, i.e., a structure consisting of elongated, interlocked grains. The recrystallization temperature is significantly higher than for pure molybdenum. Our ML wires and pins remain ductile at room temperature and at very high operating temperatures.