Andreas Feichtinger (left), Executive Vice President, at Plansee since 2008 - Ulrich Lausecker (right), Executive Vice President, with the Plansee Group since 1997.

Plansee High Performance Materials specializes in the manufacturing of components from molybdenum and tungsten. Whether in the semiconductor industry, consumer electronics, medical technology, or high-temperature furnaces, our refractory metals and composites come into play in scenarios where regular metals reach their limits. As an innovation partner, together with our customers we develop sustainable solutions for the high-tech world and continually push the boundaries of what is technologically feasible.

Founded in 1921 in Reutte, Austria, today we are a global and independent private company. We employ around 3,500 people at more than 10 production sites in Asia, the USA, and Europe and have a global sales network. For more than 100 years, Plansee has stood for reliability and stability. This is also reflected in the long-standing company affiliation of our management board.

Andreas Feichtinger (left), Executive Vice President, at Plansee since 2008 - Ulrich Lausecker (right), Executive Vice President, with the Plansee Group since 1997.

Privately owned company with a success story spanning 100 years

Sustainable value chain from the raw material to the finished product

Powder metallurgy manufacturing process

Proximity to customers through more than 10 production sites

Innovation partner from prototype development to series production

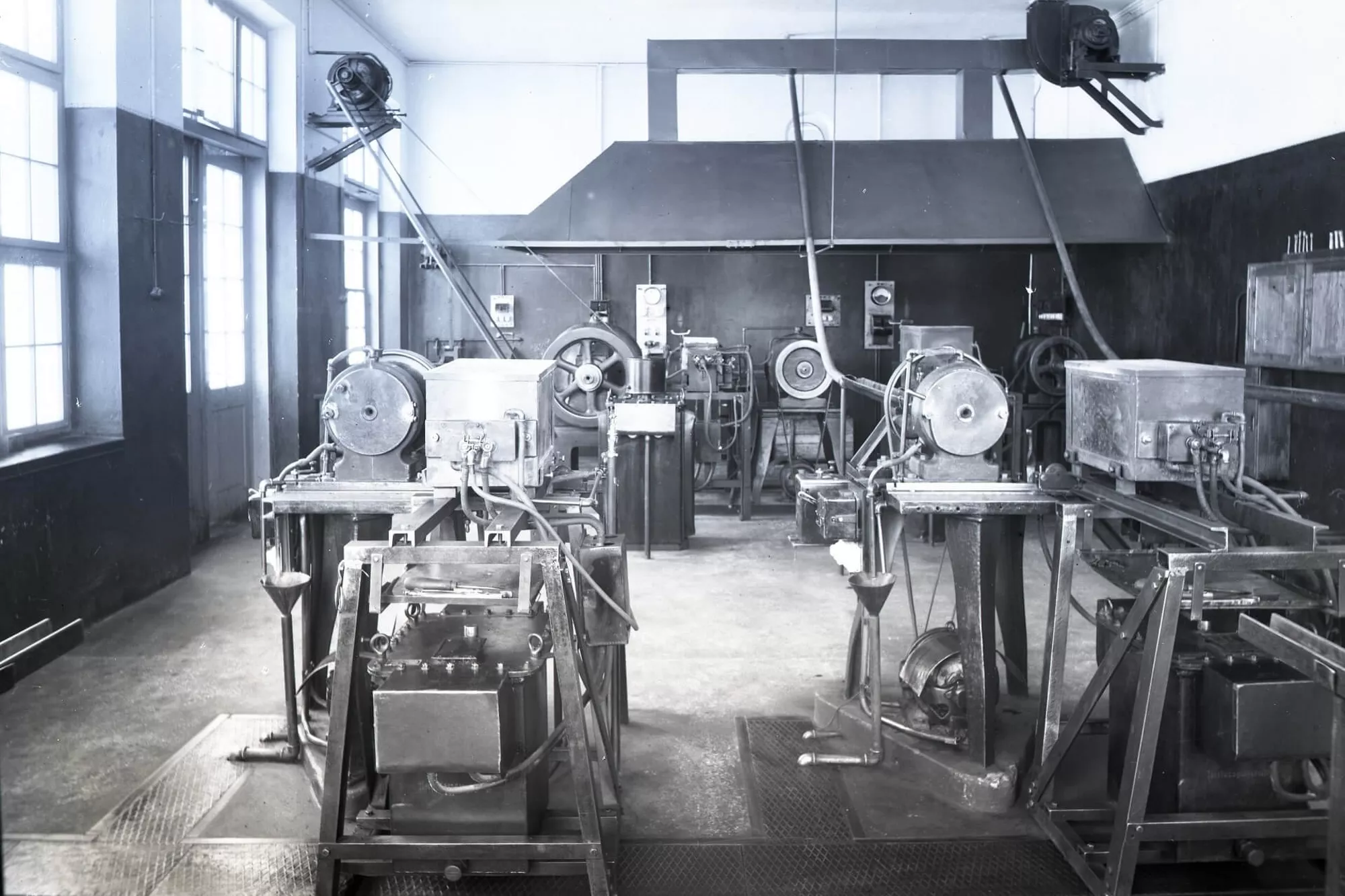

On June 24, 1921, Paul Schwarzkopf from Prague founds Metallwerk Plansee Gesellschaft m.b.H with his business partner Richard Kurtz in Breitenwang/Reutte, Tyrol. A year later, the production of tungsten wires begins.

The water of the Plansee is an important energy source for the company, which is why the lake is a decisive factor in choosing the location and name of the company.

The company starts producing tungsten wires for incandescent lamps with 15 employees. Tungsten wires are followed in 1923 by wires made of molybdenum and, from the late 1920s, the production of the carbide titanite.

In 1925, Paul Schwarzkopf expands into the USA and founds the Plansee USA production site in Franklin in 1929.

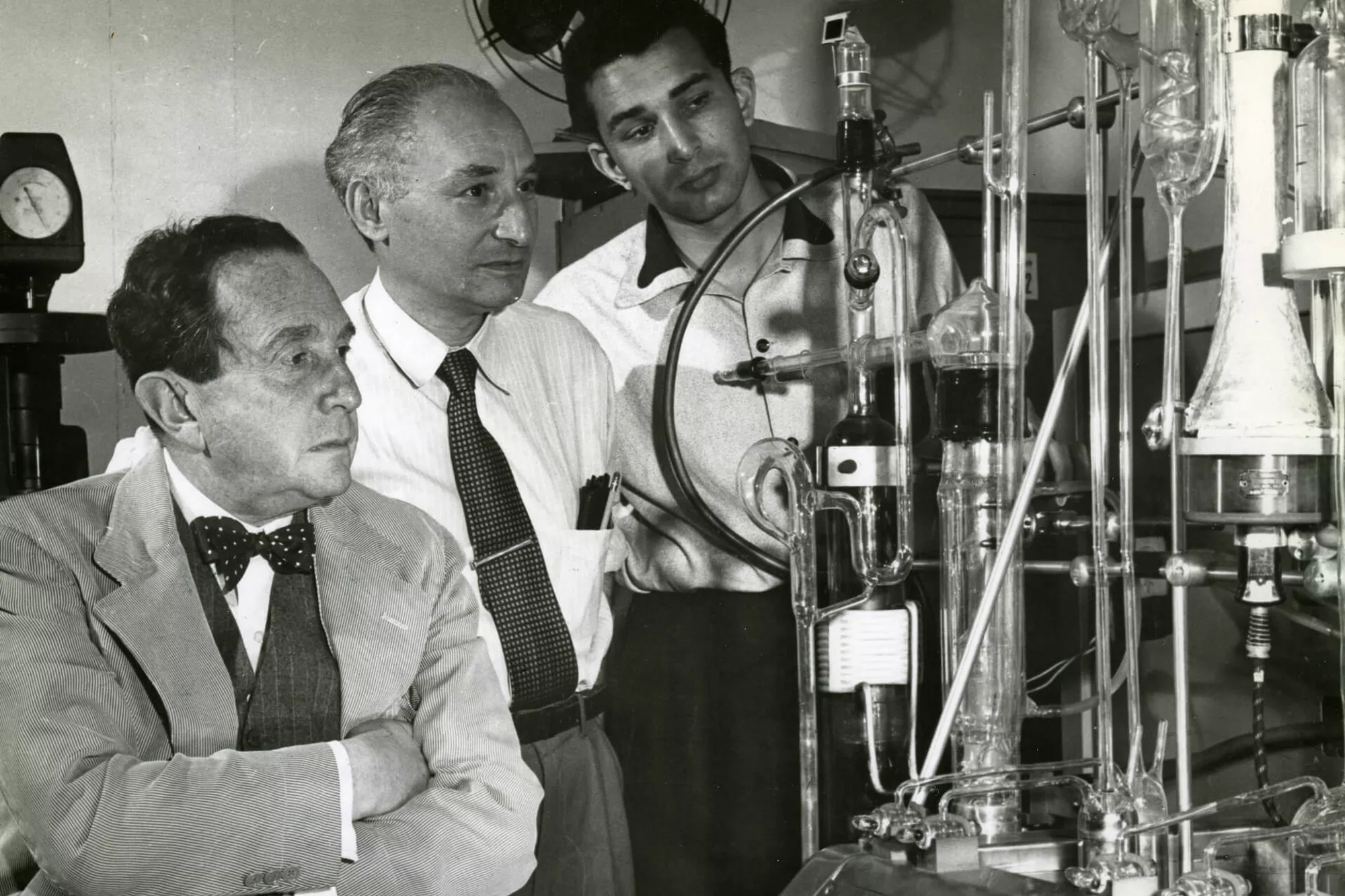

In 1952, Paul Schwarzkopf launches the Plansee Seminar, a meeting about material science and materials engineering that takes place every four years. At this seminar, powder metallurgy experts present their knowledge on the development, production, and application of refractory metals.

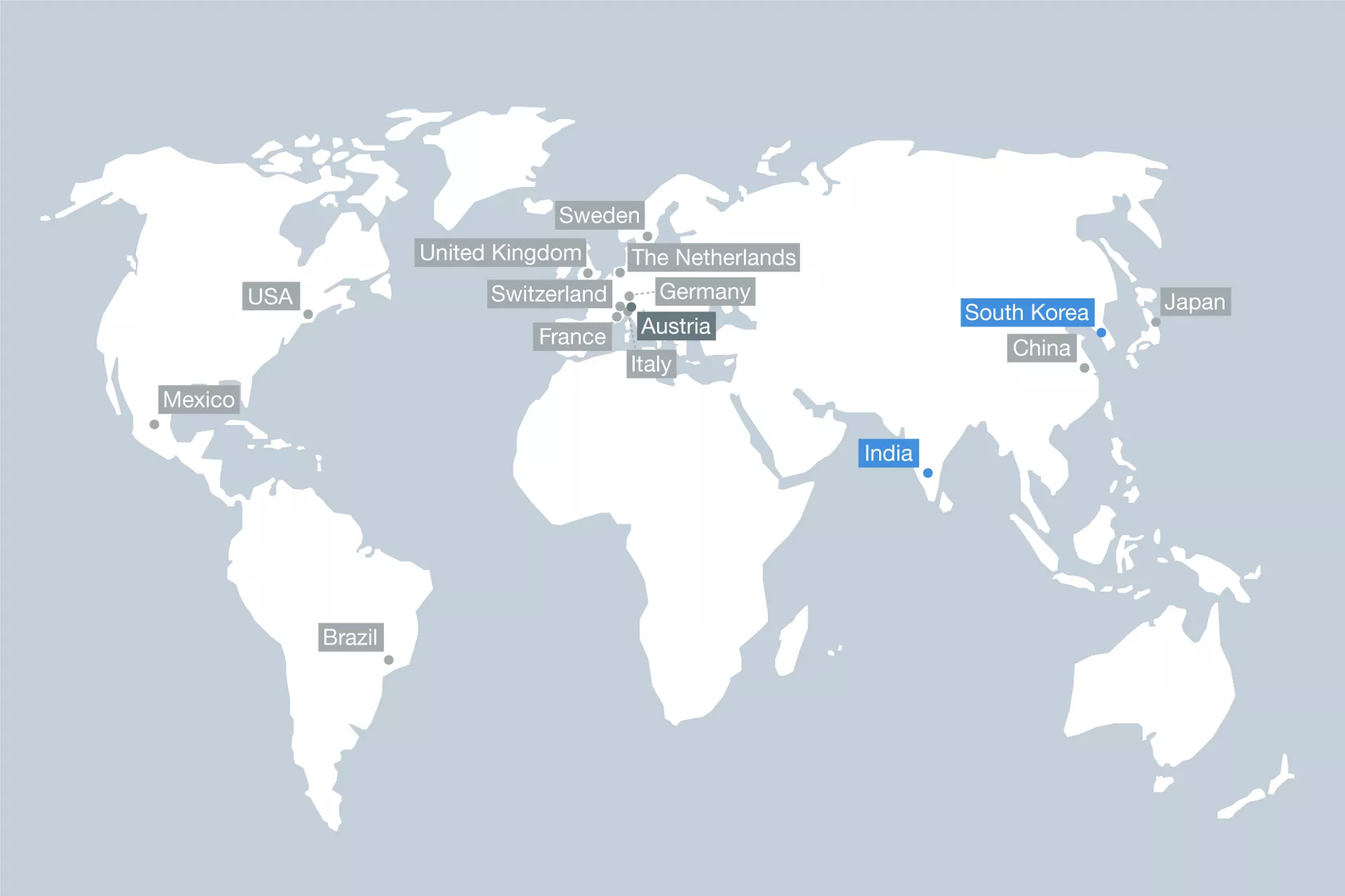

After Walter Schwarzkopf's death in 1978, his widow Hilde Schwarzkopf takes over the management of the company and founds various sales companies worldwide, including in Japan, Germany, Great Britain, France, Italy, Switzerland, the Netherlands, Sweden, Brazil, Mexico, and China.

From 1996 to 2017, Michael Schwarzkopf, son of Walter Schwarzkopf, manages the company. Since then, he has been the Chairman of the Supervisory Board.

Expansion into other markets, particularly Asia, takes place with Wolfra-Tech Pvt. Ltd. in Mysore, India and with TCB Korea Co., Ltd. in South Korea, among others.

On June 21, 2021, the Plansee Group celebrates its 100th anniversary. What first began with the production of tungsten wire, has grown and grown. Today, Plansee manufactures over 75,000 products for numerous industries.

Today, Plansee is a global leader in powder metallurgy and operates across 32 sites in 24 countries. It has more than 10 production sites across the USA, Europe, and Asia. Our international supply chain and production network guarantees security of supply for our customers.

€ annual sales 2022

employees

patents

production sites

Security, trust, and sustainability: we still stand for these values after 100 years. The company was founded in 1921 near the Plansee. It is not only our namesake but also our energy source and more important today than ever. Whether it relates to hydroelectric power, sustainable company management, recycling of materials, or global compliance with labor laws, sustainability has always had many dimensions at Plansee.

Hence, our responsibility towards our customers and the environment is deeply rooted in our company. A long-term security of supply is part of our sustainable business development. With our companies and holdings in mines in the West, we guarantee a secure raw material supply. We are committed to transparency and certifications, and ensure via numerous measures that we do not use any raw materials which come from socially, ethically, or ecologically questionable sources. We also are constantly investing in new technology so that we will remain a reliable partner in the future.

Learn more about Plansee and make use of our comprehensive sources of information:

Our company values have always shaped the culture of Plansee. They are the bedrock upon which we build our relationships with each other and our partners.

The Plansee Group is focused on the production and marketing of the refractory metals molybdenum and tungsten: Plansee specializes in the processing of molybdenum and tungsten into semifinished products and components. Ceratizit processes tungsten carbide into tools.

The Plansee Group guarantees a sustainable raw material supply. The supply of our key raw materials molybdenum and tungsten is guaranteed by the companies Global Tungsten & Powders and Molymet.

More information about the company group can be found here: