From powder to the final product

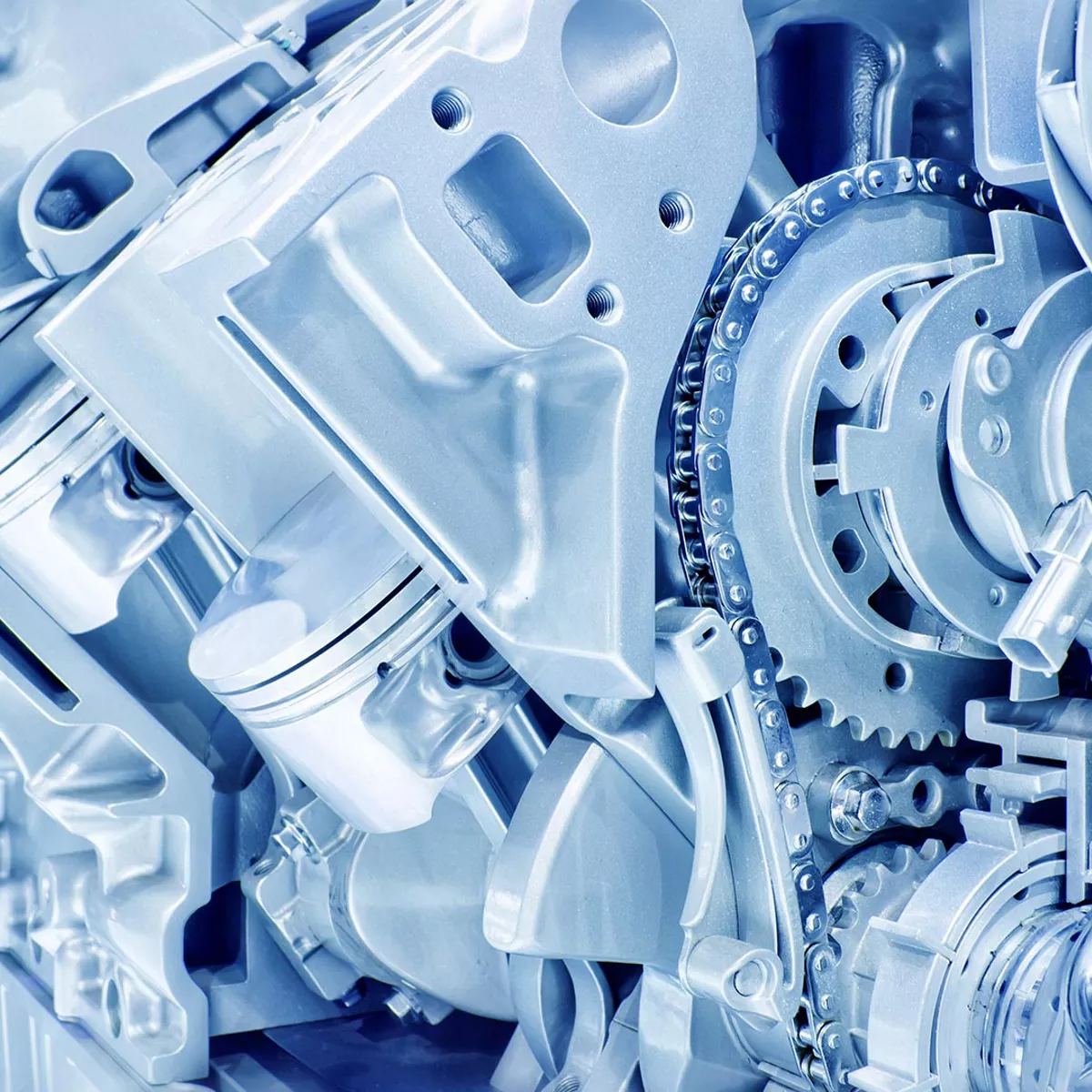

With decades of experience in the manufacturing of high-quality products made from refractory metals, you can count on us to be your reliable and sustainable partner. We only invest in Western mines to secure responsible and sustainable raw materials. How do we guarantee our high quality standards? By ensuring that we do it all ourselves. Our production chain starts with the reduction of ultrapure oxide to metal powder. This is how we control the material properties. Then we manufacture compact, metal parts from porous powder blanks. Using special forming processes and mechanical processing steps as well as modern coating and connection technologies, we turn these into complex components.

Our materials scientists and engineers will adapt the properties of our components to your exact requirements – with the strictest manufacturing tolerances and optimal quality. We are also making continual investments in the latest, fully automatic systems to guarantee high production capacities and a reliable delivery capability.