With 100 years of experience, we develop and manufacture components and products from refractory metals for different industries at 12 production sites.

- slideplansee-aem/components/heroTeaser86256450

- slideplansee-aem/components/heroTeaser86256453

- slideplansee-aem/components/heroTeaser86256456

- slideplansee-aem/components/heroTeaser86256459

- ProgressOur measures formore sustainability

- ProgressTrade fairs and eventsWe look forward to seeing you!

- ProgressWith passion for innovation

- ProgressCO2-free Hydrogenin Reutte

Plansee: Strong metals for strong products

Plansee is a world-leading manufacturer of components from molybdenum and tungsten. Whether in electronics, coating technology, or high-temperature furnaces, where regular metals reach their limits, the refractory metals, alloys, and composite materials from Plansee come into play. As an innovation partner, together with our customers we develop sustainable solutions for the high-tech world and keep pushing the boundaries of what is technologically feasible.

Our strong, high-melting refractory metals molybdenum, tungsten, tantalum, and tungsten-based composites are considered particularly resistant. Their special material properties make them ideal for numerous high-tech applications: whether as parts for the semiconductor industry or the manufacturing of next-generation microchips, as components for generating X-rays, or as elements of solar cells.

Learn more about our strong metals:

75,000 products from refractory metals

From semifinished products to individual customer solutions, we manufacture according to the highest quality standards in our international production network.

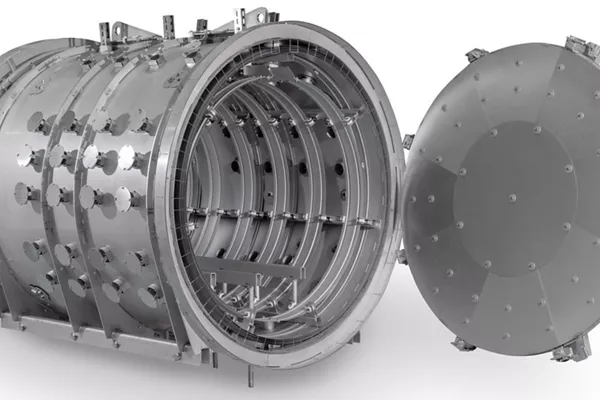

To the product overview First deliveries of the new generation of Hot Zones

First deliveries of the new generation of Hot Zones Construction Begins on New Hydrogen Electrolyzer at Plansee in Reutte, Austria

Construction Begins on New Hydrogen Electrolyzer at Plansee in Reutte, Austria UN Global Compact: Plansee Group commits to sustainable business practices

UN Global Compact: Plansee Group commits to sustainable business practices First sustainability report published

First sustainability report published- slideplansee-aem/components/newsTeaserItem86256528

- slideplansee-aem/components/newsTeaserItem86256531

- slideplansee-aem/components/newsTeaserItem86256534

- slideplansee-aem/components/newsTeaserItem86256537

- Mio.

€ annual sales 2022

employees

patents

production sites